Basic Info.

Model NO.

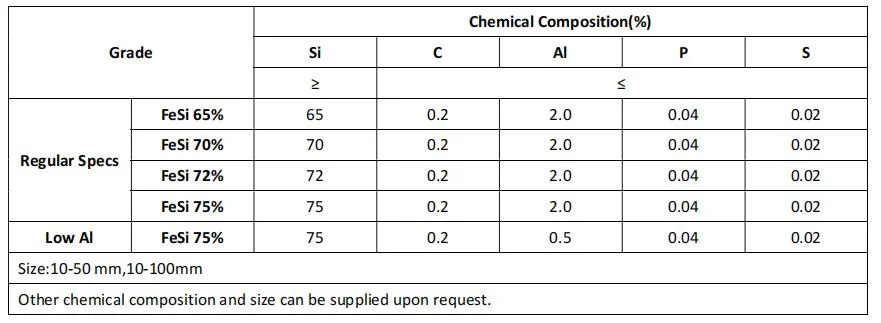

Fesi72

Origin

China

HS Code

72022100

Product Description

COMPANY PROFILE

Gansu Mingruige Trading Co., LTD , which was established in May 2000 with the approval of Gansu Provincial Bureau of Commerce, Mainly dealing with import and export business of Ferroalloys, Non-Ferrous metals and Refractory products.

MingRuiGe has established extensive and stable trade partnerships with well-known corporation and factories in more than 50 countries and regions, and the export commodities nearly covering all Steel & foundry factory demand, including Ferroalloys, Non-Ferrous Metals, Refractory Materials, Foundry chemical Products etc.

PRODUCT DESCRIPTION

Ferrosilicon is an alloy of iron and silicon. Ferrosilicon is coke, steel chips, quartz (or silica) as raw materials, with electric furnace smelting made of ferrosilicon alloy. Because silicon and oxygen are easy to combine into silicon dioxide, so iron silicon is often used as a deoxidizer in steelmaking. At the same time, due to the release of a lot of heat when SiO2 is generated, it is also favorable to improve the temperature of molten steel at the same time. At the same time, ferrosilicon can also be used as alloying element additive, widely used in low-alloy structural steel, spring steel, bearing steel, heat-resistant steel and electrical silicon steel, ferrosilicon in ferroalloy production and chemical industry, commonly used as reducing agent.Ferrosilicon alloy composed of iron and silicon (with silica, steel, coke as raw materials, after 1500-1800 degrees of high temperature reduction of silicon fused in liquid iron, forming ferrosilicon alloy). It is an important alloy variety in smelting industry.

APPLICATION

(1.) Used as deoxidizer and alloying agent in steelmaking industry. In order to obtain steel with qualified chemical composition and ensure the quality of steel, deoxidation must be carried out in the final stage of steel making. The chemical affinity between silicon and oxygen is very large, so ferrosilicon is a strong deoxidizer used in steel making for precipitation and diffusion deoxidation. Adding a certain amount of silicon to steel can significantly improve the strength, hardness and elasticity of steel.

(2.) In the cast iron industry used as inoculant and spheroidizing agent, adding a certain amount of ferrosilicon in cast iron can prevent the formation of carbide in iron, promote the precipitation and spheroidization of graphite, so in the production of nodular cast iron, ferrosilicon is an important inoculant (help precipitate graphite) and spheroidizing agent.

(3.)Used as reducing agent in ferroalloy production. Not only the chemical affinity between silicon and oxygen is great, but also the high silicon iron silicon has a very low carbon content. Therefore, high silicon ferrosilicon (or siliceous alloy) is a reducing agent commonly used in the production of low carbon ferroalloys in the ferroalloy industry.

WHY CHOSE US

Stable Quality

Professional Team and Service

Strict QC Procedures

Accept Third Party Inspection

Gansu Mingruige Trading Co., LTD , which was established in May 2000 with the approval of Gansu Provincial Bureau of Commerce, Mainly dealing with import and export business of Ferroalloys, Non-Ferrous metals and Refractory products.

MingRuiGe has established extensive and stable trade partnerships with well-known corporation and factories in more than 50 countries and regions, and the export commodities nearly covering all Steel & foundry factory demand, including Ferroalloys, Non-Ferrous Metals, Refractory Materials, Foundry chemical Products etc.

PRODUCT DESCRIPTION

Ferrosilicon is an alloy of iron and silicon. Ferrosilicon is coke, steel chips, quartz (or silica) as raw materials, with electric furnace smelting made of ferrosilicon alloy. Because silicon and oxygen are easy to combine into silicon dioxide, so iron silicon is often used as a deoxidizer in steelmaking. At the same time, due to the release of a lot of heat when SiO2 is generated, it is also favorable to improve the temperature of molten steel at the same time. At the same time, ferrosilicon can also be used as alloying element additive, widely used in low-alloy structural steel, spring steel, bearing steel, heat-resistant steel and electrical silicon steel, ferrosilicon in ferroalloy production and chemical industry, commonly used as reducing agent.Ferrosilicon alloy composed of iron and silicon (with silica, steel, coke as raw materials, after 1500-1800 degrees of high temperature reduction of silicon fused in liquid iron, forming ferrosilicon alloy). It is an important alloy variety in smelting industry.

APPLICATION

(1.) Used as deoxidizer and alloying agent in steelmaking industry. In order to obtain steel with qualified chemical composition and ensure the quality of steel, deoxidation must be carried out in the final stage of steel making. The chemical affinity between silicon and oxygen is very large, so ferrosilicon is a strong deoxidizer used in steel making for precipitation and diffusion deoxidation. Adding a certain amount of silicon to steel can significantly improve the strength, hardness and elasticity of steel.

(2.) In the cast iron industry used as inoculant and spheroidizing agent, adding a certain amount of ferrosilicon in cast iron can prevent the formation of carbide in iron, promote the precipitation and spheroidization of graphite, so in the production of nodular cast iron, ferrosilicon is an important inoculant (help precipitate graphite) and spheroidizing agent.

(3.)Used as reducing agent in ferroalloy production. Not only the chemical affinity between silicon and oxygen is great, but also the high silicon iron silicon has a very low carbon content. Therefore, high silicon ferrosilicon (or siliceous alloy) is a reducing agent commonly used in the production of low carbon ferroalloys in the ferroalloy industry.

WHY CHOSE US

Stable Quality

Professional Team and Service

Strict QC Procedures

Accept Third Party Inspection