Basic Info.

Model NO.

AISI446

Spring Module at 876ºC 104MPa

8.27

MPa Tensile Strength at 870ºC

48

Heat-Shrinking Coefficient at 870º

13.68

Heat-Conductibility at 500ºC W/M.K

26.3

Proportion at Room Temp., g/cm3

7.8

Weight Loss After Circular Oxidation Abo

70

Erosion in The H2s,Mil/Yr

200

Max Working Temp. in The So2 ,ºC

800

Erosion in The Natural Gas at 815º

12

Erosion in The Coal Gas From The Cookery

236

Nitrification in The Anhydrous Ammonia a

80-175

Erosion in The H2,at 454ºC,Mil/Yr

21.9

Carbon Content of The Alloy After Solid

1.03

Transport Package

Moisture-Proof Carton or Paper Bag

Specification

0.3*1*25mm

Trademark

xuanhua

Origin

Zhengzhou, China

Production Capacity

3600 Tons/Year

Product Description

Heat Shock Resistance 446 Melt Extract Steel Fibers stainless steel fiber for kiln

1.SpecificationPlace of Origin: zhengzhou,China

Model Number:304,310,330,430,446

Standard:ASTM/AISI/ISO/CE

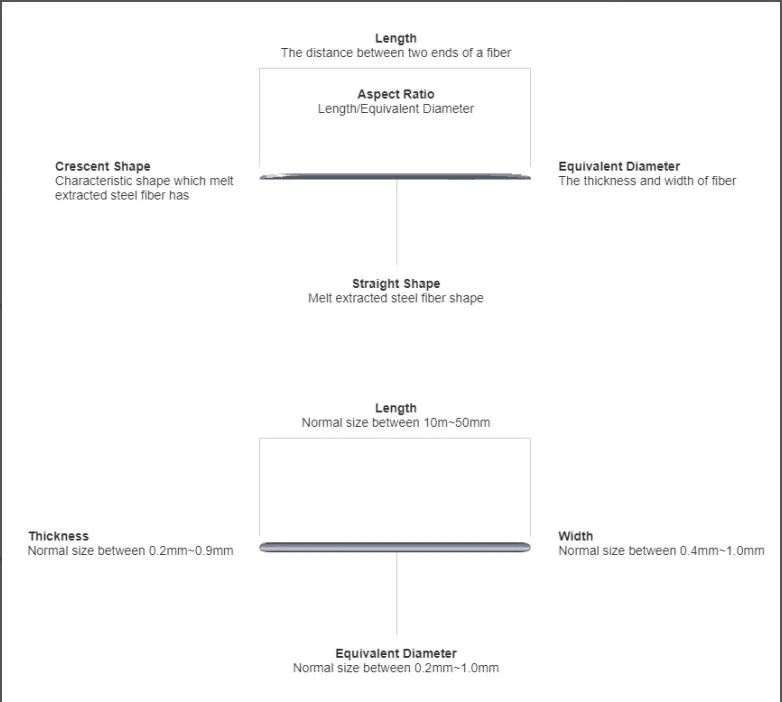

Length:19mm/25mm/35mm or customized

Material:Stainless Steel

Melting Point:Greater than 1500C

Brand Name:XuanHua

Feature:high temperature resistance, corrosion resistance, oxidation resistance, tensile resistance, wear resistance, increased strength, heat shock resistance

Types:Melt Extracted

Diameter:0.3mm-0.5mm

Application:Refractory Industry

Supply Ability:300 Ton/Tons per Month

Packaging Details:PACKED BY CARTON BOXES WITH PALLET, 20KGS/CARTON, 50 CARTONS/PALLET ( NET WEIGHT 1000KG ON A PALLET).13pallets in 20'

Port: Tianjin Port or Qingdao

Shape:needle/pipe/Crescent Shape

| SIZE | |||||||

| C | P | Mn | Si | Cr | Ni | ||

| AISI330 | ≤0.30 | ≤0.04 | ≤2.00 | ≤0.75 | 17~20 | 33~37 | |

| AISI310* | ≤0.30 | ≤0.04 | ≤2.00 | ≤1.50 | 24~26 | 19~22 | |

| AISI316 | ≤0.30 | ≤0.04 | ≤2.00 | ≤1.00 | 16~18 | 10~14 | |

| AISI314 | ≤0.30 | ≤0.045 | ≤2.00 | 1.5-3.0 | 23~26 | 19~22 | |

| AISI309 | ≤0.30 | ≤0.04 | ≤2.00 | ≤1.00 | 22~24 | 12~15 | |

| AISI304* | ≤0.30 | ≤0.04 | ≤2.00 | ≤2.00 | 18~20 | 8~10 | |

| AISI301 | ≤0.30 | ≤0.04 | ≤2.00 | ≤2.00 | 16~18 | 6~8 | |

| AISI201 | ≤0.30 | ≤0.06 | 5.5~7.5 | ≤1.00 | 16~18 | 3.5~5.5 | |

| AISI446* | ≤0.30 | ≤0.04 | ≤1.50 | ≤2.00 | 23~27 | ||

| AISI430* | ≤0.30 | ≤0.03 | ≤1.00 | ≤2.00 | 16~18 | ||

2.Application

1. Metallurgical industry

The refining outside the furnace airbrush, dipping tubes, slag dam, bag lining cover, the triangle electric furnace, furnace cover, the molten iron trench cover, aluminum melting furnace,the torpedo cans, coke oven door, the heating furnace of steel rolling door, furnace roof, burn top, annular furnace baffle wall, hearth roll, forging steel furnace, steel tanks etc, items can be used for various refractory kiln linings.

2. Cement industry

Cement rotary kiln exit,cooler,coal burner,kiln calciner,preheater and other parts

3. Kiln

Sintering furnace, reduction furnace, finer, the flue, furnace burning top and other heat-resistant linings.

4. Petroleum chemical industry

Especially in the refining the lining of catalytic cracking units.

5. Electric power industry

Thermal power plant boiler heat resistant linings.

6. Environmental protection industry

Incinerator.

7. Machinery Industry

Vibrating furnace bottom, various heating furnaces.

3.Package

Carton:

20kg/carton,50 boxes/pallet,1pallet net weight 1000kg.

Carton size:250*250*250mm

Paper Bag:

20kg/bag,50 bags/pallet,1pallet net weight 1000kg.

4.Production Process

The raw material is stainless steel ingots, using electric stoves which melt the stainless steel ingots to become 1500 ~ 1600 ºC steel liquid, and then with a grooved high speed rotating melt-extracting steel wheel which produces wires that meets are our customers' specific requirements. When melting down to a wheel steel liquid surface, the liquid steel blow out by slot with centrifugal force at extremely high speed with cooling forming. Melting wheels with water keep the cooling speed. This method is done to produce different material, different sizes of steel fiber.

5. Enterprise Photoes

6.Q&A

Q1: Are you a trading company or a manufacturer?

We are a manufacturer. Since 2010, we are specialized in steel fiber manufacturing and R&D. We are located in Zhengzhou, Henan Province, with 10000 M 2 production base. With multiple types of steel fiber production equipment, our production speed is 10 tons per day. Our products are widely praised in China and strictly comply with international standards. We have in-depth cooperation with Shanghai Jingpu Technology Co., LTD., and the quality of our products is guaranteed. These fibers comply with YB/TlSl-1999 standards. The products are mainly used in high temperature industrial kilns and concrete construction industry.

Q2: Do you accept customized products?

Yes, we provide customized services to our customers, from product types, specifications, quality requirements, packing forms and modes of transportation to meet their different needs.

Q3: What about the shipment?

We will choose the right mode of transportation according to customer's requirement. Usually by sea or by rail.

Q4: Is a trial order acceptable?

Yes, the lower minimum order quantity is always accepted for quality and market assessment

Q5: What are the terms of payment?

30% in advance, name of port or unloading address, 70% payment.

Q6: How do you ensure the quality of your products?

Each batch of products will be instrumented and a product test sheet will be attached. If customers need, samples can be randomly selected by the third party testing company to issue testing certificate, to ensure the quality of goods.

Q7: When can you receive the goods after submitting the order?

Sample orders: 1-3 days; Mass production: 15-20 working days.