Basic Info.

Model NO.

have sth. made to order

Fire Resistance

1690°c

Porosity

25%

Normal Temperature Compressive Strength

40MPa

Rate of Change of Refiring Line

-0.1-+0.3(1500°c×2h)%

Load Softening Onset Temperature

≥1600°c

Bulk Density

≥2.50(2.45)

Transport Package

Wooden Pallet

Specification

230-115-65

Trademark

Hongzhengda Refractory

Origin

Chengdu, Sichuan

HS Code

6902200000

Production Capacity

50, 000 Tonnes/Year

Product Description

Product description

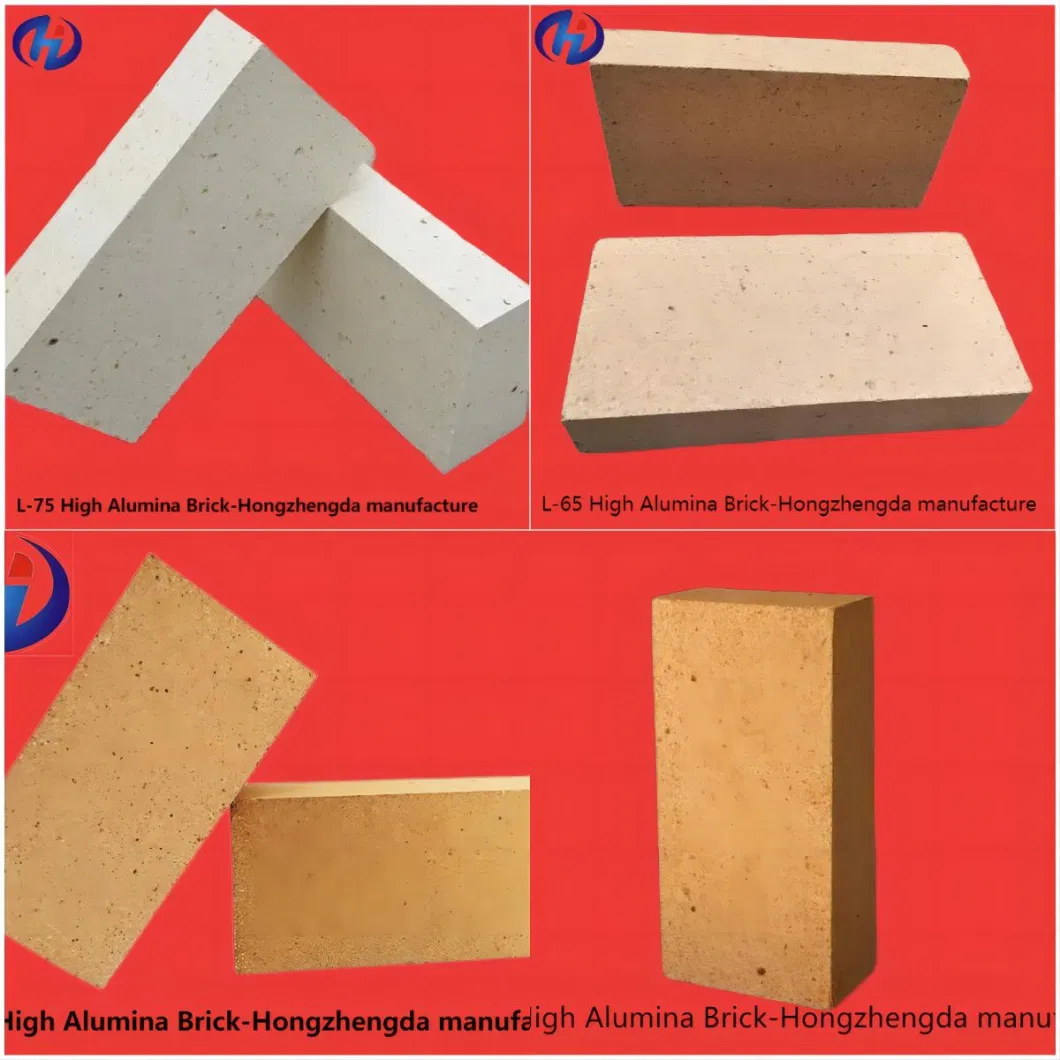

High Alumina Brick:

High alumina brick production process: high alumina ore (AI2O3 content of higher aluminium ore) as the main raw material, high purity alumina powder, etc., auxiliary raw materials, soft kaolin as a binder.

Clinker by grading classified sieve, particle grading, stirring evenly, the formation of mortar-like material, the

Brick Forming: Load the material into the mould, use pressure and vibration to exhaust and press, according to the grade of high alumina bricks, adjust the pressure of the equipment, so that the bricks reach the standard.

Drying: The moulded bricks are put in the drying room for natural drying and preheating drying by kiln, controlling the drying time and temperature to ensure that the moisture inside the bricks is fully evaporated.

Sintering: Push the brick billets from the drying room to the sintering kiln at regular intervals and under high temperature conditions, combine the material particles of the brick billets through high temperature sintering to form a dense crystalline structure, and control the time and temperature of sintering to ensure the mechanical strength and refractory performance of the high alumina bricks.

Cooling and packaging: Timing from the sintering kiln to the cooling section, cooling, control the cold time, after the cold time, push out from the kiln, according to the brick type, according to the customer's requirements for packaging.

Part of the company's project co-operation

Reasons to choose us

Reasons to choose us

Years of industry experience and trustworthy products.

Focusing on R&D and manufacturing of refractory materials.

Quality assured, fast delivery.

Delivery without worry, rest assured procurement.

Manufacturer manufacturing. Processing customised.

Company strength display

Years of industry experience, products are trustworthy.

Company Strength Display

Company Strength Display

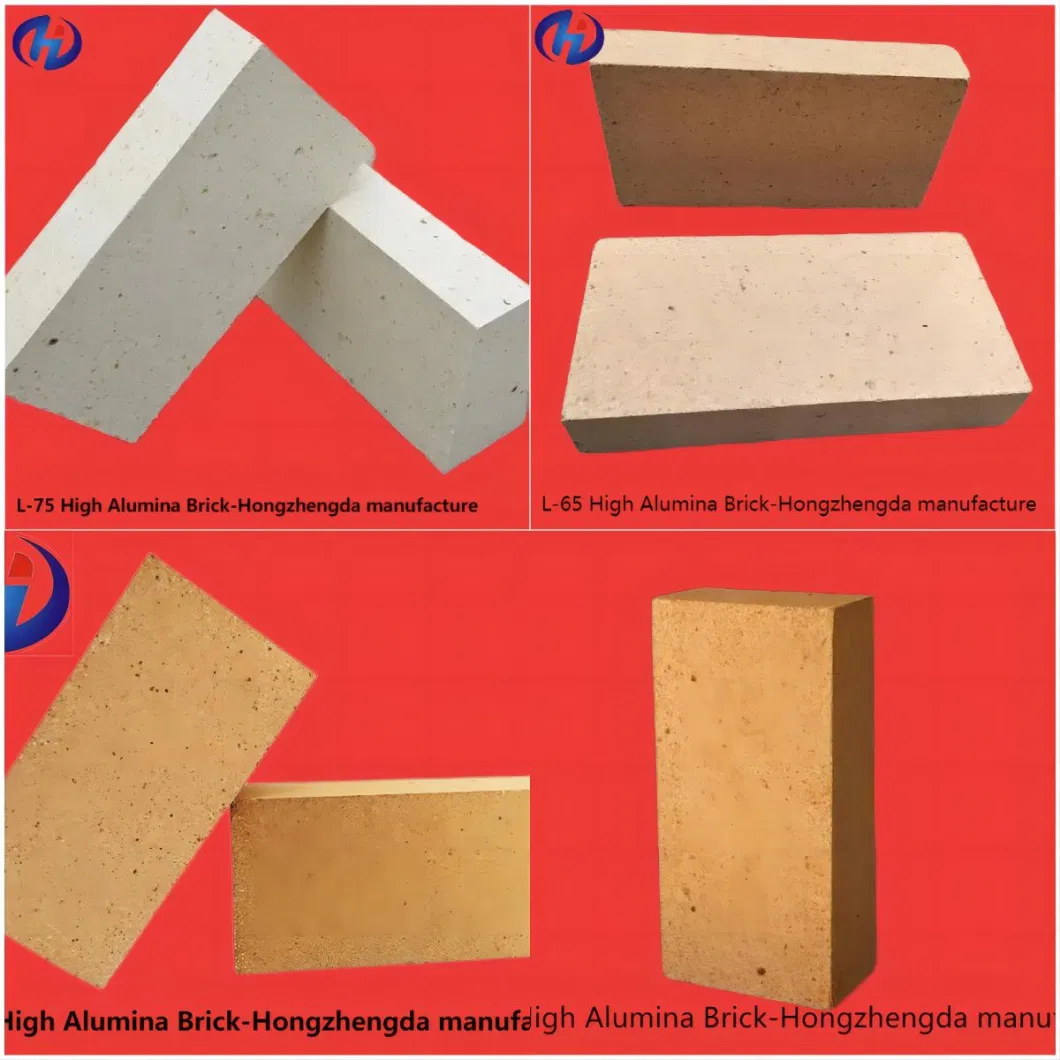

High Alumina Brick:

High alumina brick production process: high alumina ore (AI2O3 content of higher aluminium ore) as the main raw material, high purity alumina powder, etc., auxiliary raw materials, soft kaolin as a binder.

Clinker by grading classified sieve, particle grading, stirring evenly, the formation of mortar-like material, the

Brick Forming: Load the material into the mould, use pressure and vibration to exhaust and press, according to the grade of high alumina bricks, adjust the pressure of the equipment, so that the bricks reach the standard.

Drying: The moulded bricks are put in the drying room for natural drying and preheating drying by kiln, controlling the drying time and temperature to ensure that the moisture inside the bricks is fully evaporated.

Sintering: Push the brick billets from the drying room to the sintering kiln at regular intervals and under high temperature conditions, combine the material particles of the brick billets through high temperature sintering to form a dense crystalline structure, and control the time and temperature of sintering to ensure the mechanical strength and refractory performance of the high alumina bricks.

Cooling and packaging: Timing from the sintering kiln to the cooling section, cooling, control the cold time, after the cold time, push out from the kiln, according to the brick type, according to the customer's requirements for packaging.

| Al2O3 | ≥ 55% |

| fire resistance | ≥1690°C |

| Porosity | ≤25% |

| Normal temperature compressive strength | ≥40MPa |

| Rate of change of refiring line | -0.1-+0.3(1500°C×2h)% |

| Load softening onset temperature | ≥1600°C |

| Bulk density | ≥2.50(2.45) |

Part of the company's project co-operation

Reasons to choose us

Reasons to choose us Years of industry experience and trustworthy products.

Focusing on R&D and manufacturing of refractory materials.

Quality assured, fast delivery.

Delivery without worry, rest assured procurement.

Manufacturer manufacturing. Processing customised.

Company strength display

Years of industry experience, products are trustworthy.

Company Strength Display

Company Strength Display