Basic Info.

Material

Aluminum

Application

Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

Surface Treatment

Powder Coating or as Specified

Color

as Required

Shipping Method

by Sea or by Air

Manufacturing Method

CNC Machining

Tolerance

as Required

Quality Control

100% QC Inspection

Drawing Format

STP, Igs, Pdf, CAD, Dwg

Size

Customized

Sample Time

Within 3-5 Days Depends on Parts

Payment Term

T/T and Others

Surface Finish

0.8 or 1.6 or 3.2 and as Required

Mill Cert.

Available

3rd Party Material Test

Available

Heat Treatment

as Required

on-Site Inspection

Available

Transport Package

Carton Box and Crate

Specification

as required

Trademark

No

Origin

Guangdong

Production Capacity

5000PCS/Month

Product Description

Part 1: What does Can Connect do?

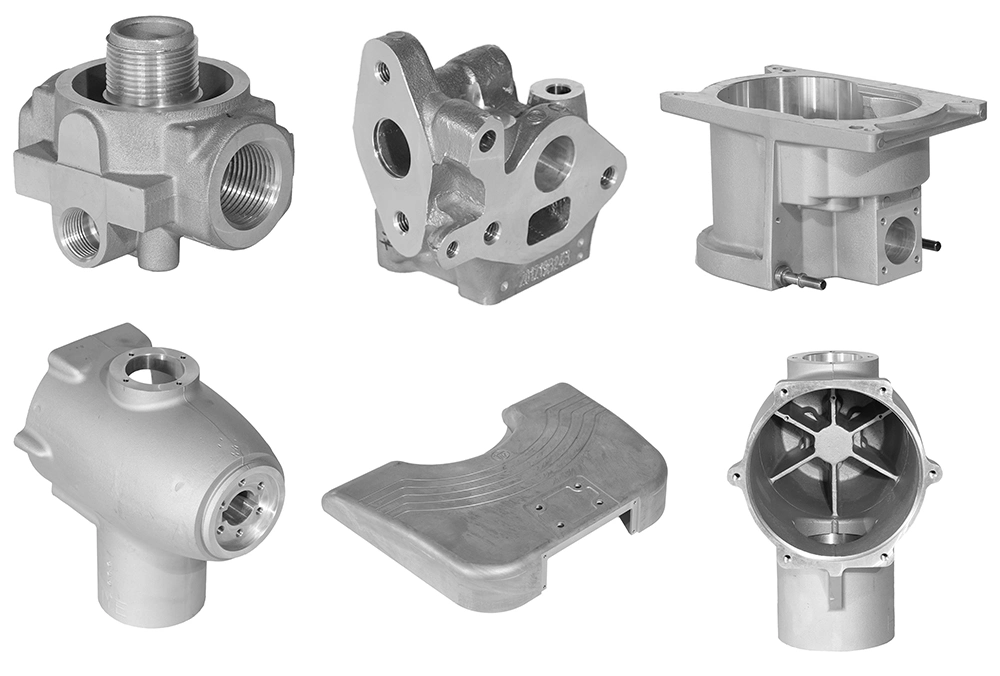

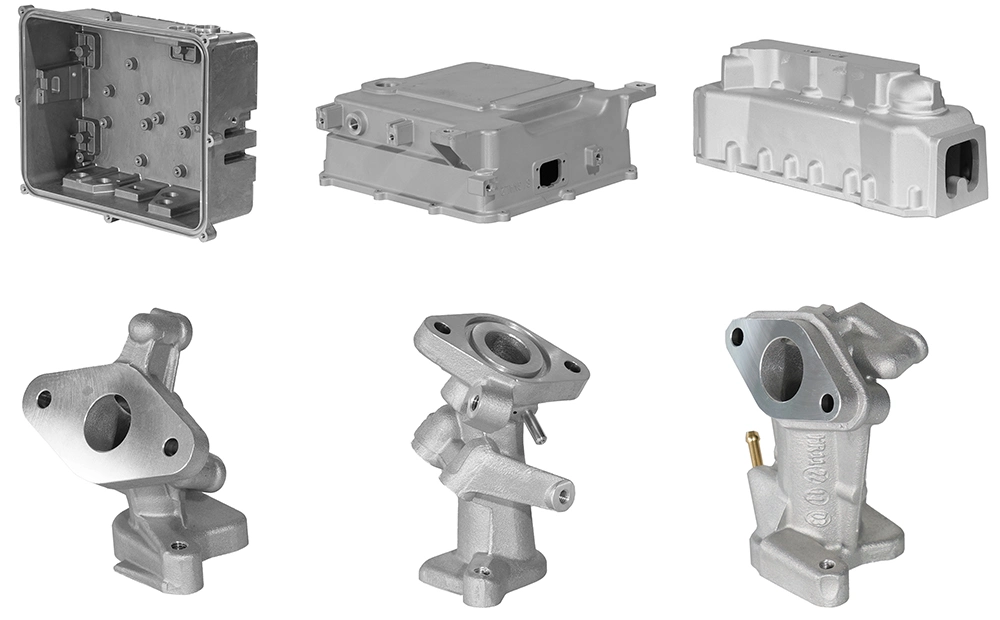

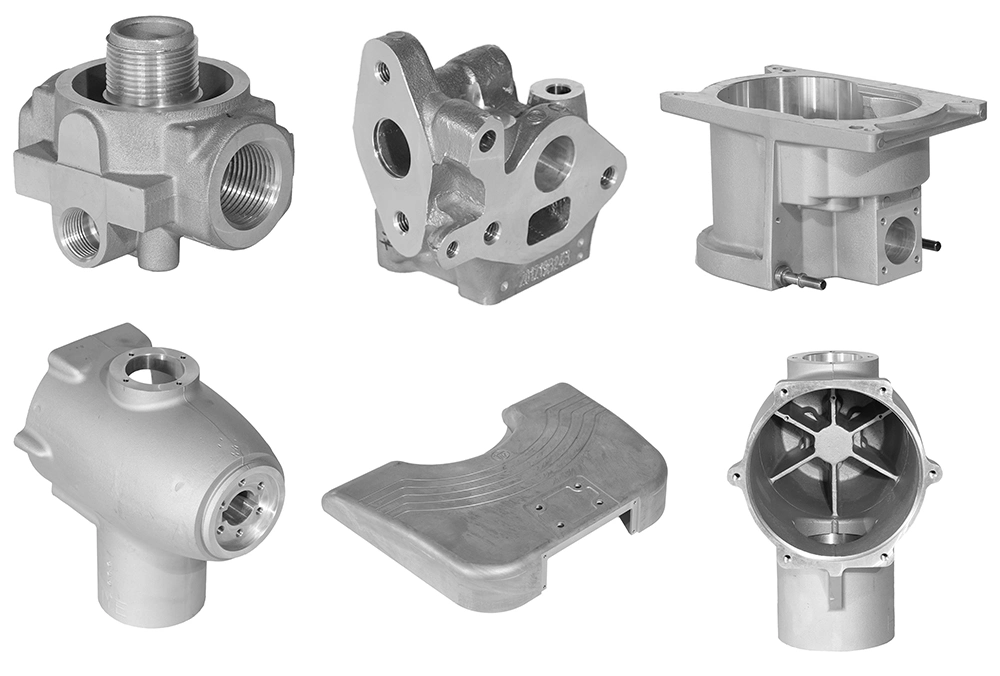

We, Can Connect Ltd, as an experienced manufacturing company for metal parts, is committed to providing customers with one-stop shopping solution for projects or products that require multiple manufacturing processes. From fabrication and CNC machining to gravity casting, investment casting and pressure die casting-you name it.

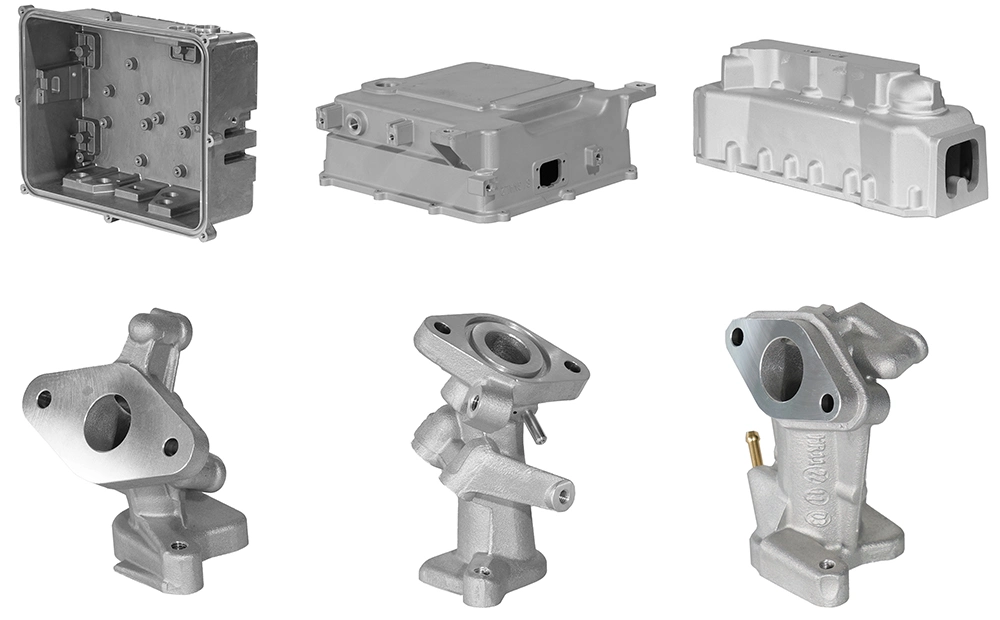

Part 2: Casting(High pressure and Gravity) Workshop & CNC Machine Workshop

We have equipped with advanced machines and equipment to be capable of making any parts against drawings and inspecting them to your requirements. Here are a portion of our manufacturing equipment to show you.

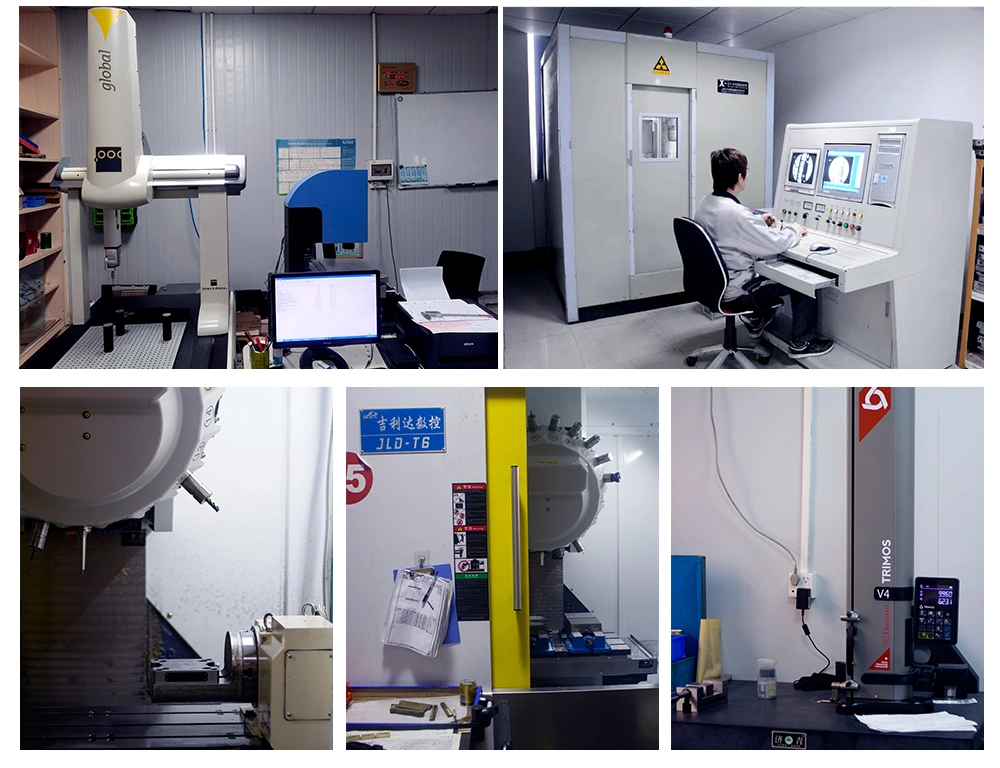

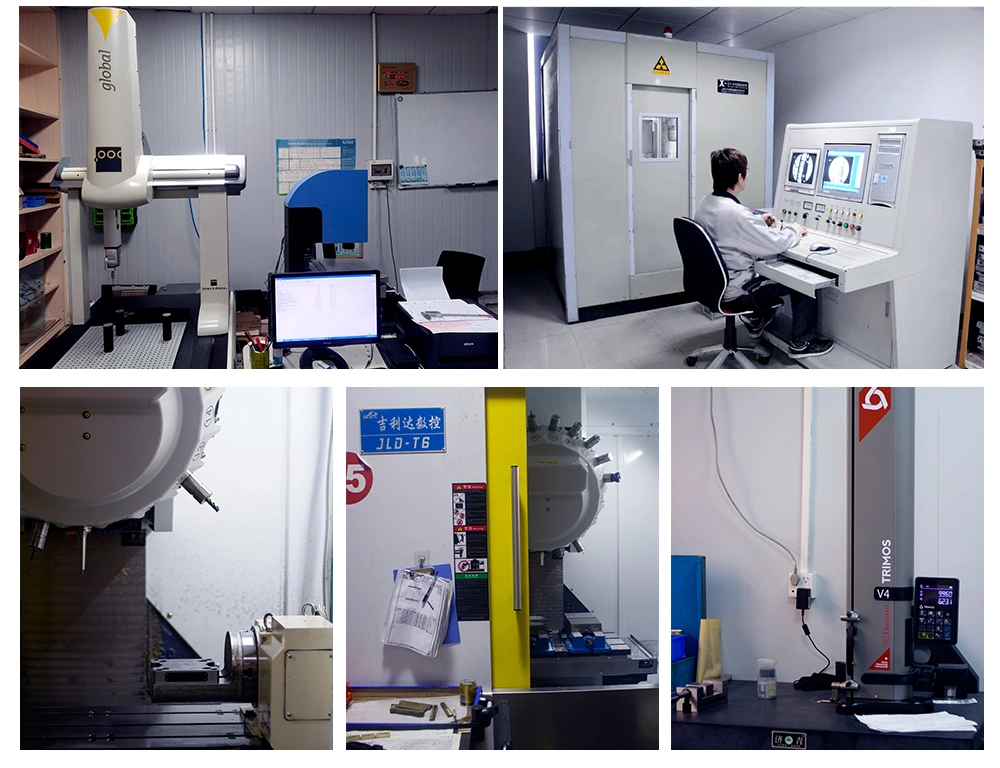

Part 3: Quality Control Equipment

Part 3: Quality Control Equipment

As always, quality control is our key to our success and trademark. We equiped with modern and sophisticated inspection instruments and equipment along with a strong and well trained QC team to guarantee every made part leaving our shop flawless.

Part 4: Frequently Asked Questions

Part 4: Frequently Asked Questions

We, Can Connect Ltd, as an experienced manufacturing company for metal parts, is committed to providing customers with one-stop shopping solution for projects or products that require multiple manufacturing processes. From fabrication and CNC machining to gravity casting, investment casting and pressure die casting-you name it.

Part 2: Casting(High pressure and Gravity) Workshop & CNC Machine Workshop

We have equipped with advanced machines and equipment to be capable of making any parts against drawings and inspecting them to your requirements. Here are a portion of our manufacturing equipment to show you.

| Equipment Name | Specification | Brand | Quantity |

| High pressure die casting machine | 2500T, Fully Automatic | Imported-Japan Toshiba | 1 |

| 1650T/1600T,Fully Automatic | Imported-Japan Toshiba | 3 | |

| 1250T,Fully Automatic | Imported-Japan Toshiba | 1 | |

| 850T,Fully Automatic | Imported-Japan Toshiba | 1 | |

| 530T/650T,Fully Automatic | Imported-Japan Toshiba | 1 of each | |

| 300T,Fully Automatic | Imported-Japan Toshiba | 1 | |

| 1500mm Static Machine | 1500mm Static Machine,Fully Automatic | Domestic well-known | 1 |

| 1500mm Auto Line,Fully Automatic | Domestic well-known | 5 | |

| 1500mm Manual Line,Fully Automatic | Domestic well-known | 4 | |

| 1000mm Manual Line,Fully Automatic | Domestic well-known | 2 | |

| CNC Machine | 4 Axis | Brothers or Haas | 80 |

| 5 Axis | Brothers or Haas | ||

| others | China well-known brand |

Part 3: Quality Control Equipment

Part 3: Quality Control EquipmentAs always, quality control is our key to our success and trademark. We equiped with modern and sophisticated inspection instruments and equipment along with a strong and well trained QC team to guarantee every made part leaving our shop flawless.

| Equipment Name | Specification | Brand | Quantity |

| X-ray Detection | Domestic well-known | 1 | |

| Direct-reading Spectrometer | Domestic well-known | 1 | |

| Universal Testing Machine | Domestic well-known | 1 | |

| 3D Scanner | Domestic well-known | 1 | |

| Hardness Tester | Brinell & Rockwell | Domestic well-known | 1 |

| Enhanced Image Measurement Instrument | Domestic well-known | 1 | |

| Laser Diameter Tester | Domestic well-known | 1 | |

| Air Leakage Tester | Domestic well-known | 2 | |

| Air-tight Tester | Domestic well-known | 2 | |

| CMM | Imported | 2 | |

| Others | Many |

Part 4: Frequently Asked Questions

Part 4: Frequently Asked Questions 1. How quick can you quote?

Within 24 hrs if we have detailed drawings and requirements. 2. What information do you need for quoting?

Kindly please provide the 2D/3D drawings (PDF/DWG/DXF/IGS/STP/SLDPRT/etc) and advise material, finish, quantity. 3. What's the MoQ for parts?

Mainly subject to your parts or projects, but we are willing to make prototypes for you as a small quantity test run. 4. What's the normal production lead time?

For initial samples, within 10-15 days. 30 days for mass production; but If mold is required, please add 20-40 days. 5. What about the after-sales service?

Please feel free to contact us for any quality issues, we will take responsible for any products with quality issues at our expenses, meanwhile, we will track down and record the issues to avoid them for the future. 6. What are your payment terms?

30% down payment before production by T/T; 70% balance to be paid upon production completion. 7. Will my drawings or samples be safe after sent to you?

Yes, we are willing to sign NDA with you if required, your drawings and samples will be kept well and maintain confidential.