Basic Info.

Model NO.

Incinerator grate blocks side walls

Surface Roughness

Ra6.3

Machining Tolerance

+/-0.01mm

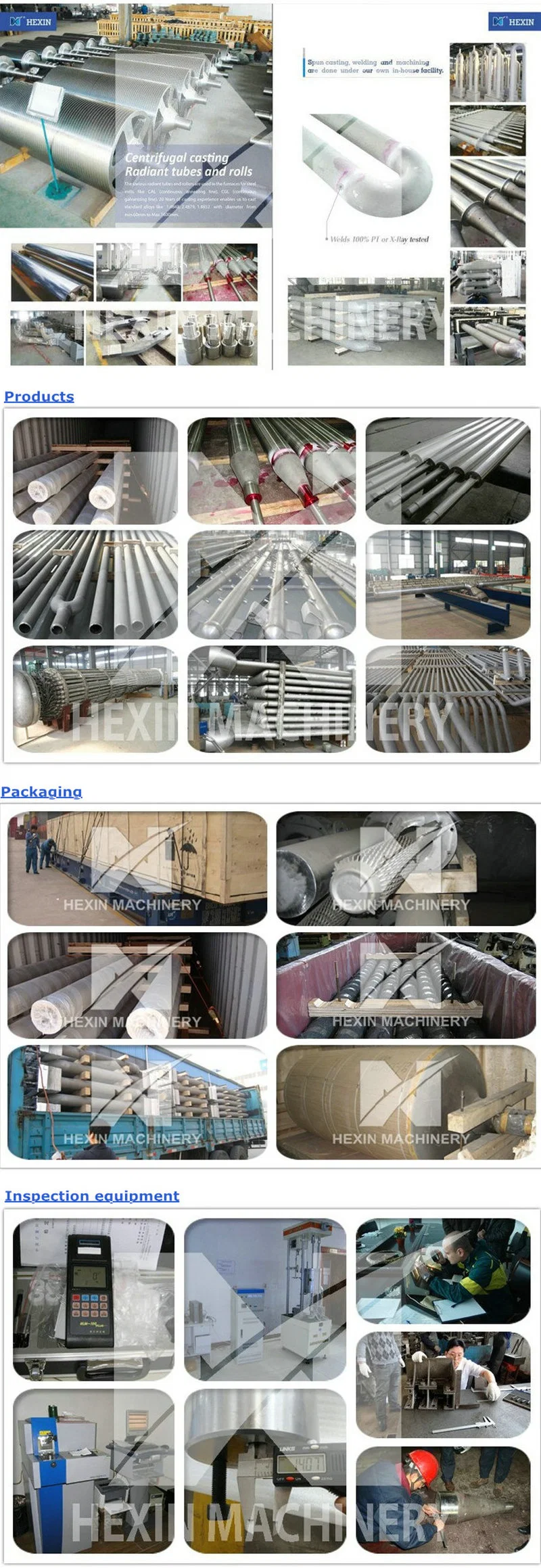

Transport Package

Wooden Case

Specification

Outer diameter: 55mm-2000mm or customized

Trademark

HEXIN

Origin

China

HS Code

85149090

Production Capacity

5000pieces/Year

Product Description

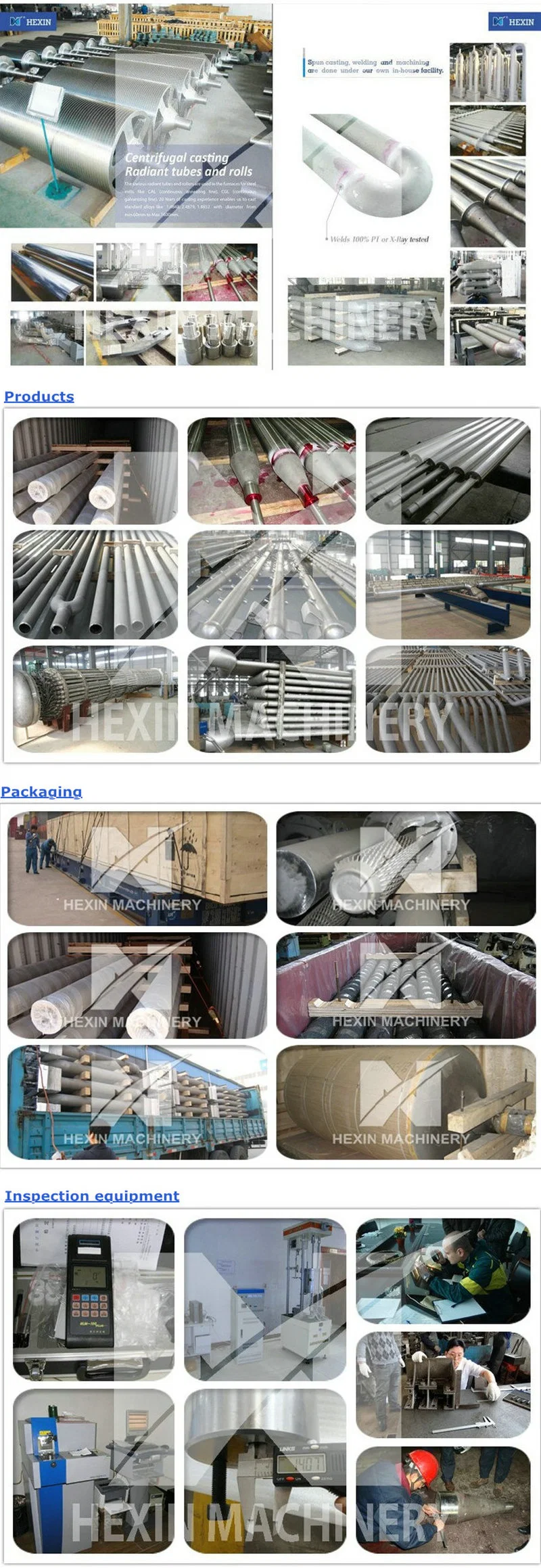

Qingdao Hexin Machinery Co., Ltd. are professional Centrifugal Casting Sink Roll for Continue Galvanizing Line, Centrifugal Casting Sink Rolls, Centrifugal Casting Rolls, Stabilizer rolls, Furnace rolls for plate heating furnace, Rolls for CAL, Water cooled rolls, Coated rolls manufacturer from China.

Qingdao Hexin Machinery Co., Ltd. produces furnace bottom rolls,which it adopt the centrifugal casting, precisely casting technology on journal bell mouth, shaft head with forging process. It can be transported with using professional wood packaging to the packing, its excellent quality has won high praise at home and abroad.

The grate system is the core part of the grate type waste incinerator.

It plays a vital role in the overall process route, incineration effect, project cost, economic benefit, etc.

The waste incineration grate is mainly composed of reciprocating moving parts.

The garbage is pushed onto the grate through the feeding device, heated at high temperature in the furnace, so that part of the garbage can be dried, and the garbage is pushed forward by the movement of the grate.

At the same time, the garbage layer is loosened, and the fuel (garbage) is gradually passed through the various stages of drying, ignition, burning, and burnout to make it completely burnt.

About us

Qingdao Hexin Machinery Co., Ltd. is professional for manufacturing, sale and research of high temperature alloy centrifugal cast tube, Heat resistant steel precision castings and sand mold casting.

The main products are: Ethylene cracking furnace furnace tube, reformer furnace tube, all kinds of casting alloy elbow, casting tube sheet, hook, hanger, bracket and other heat resistant casting products. Furnace rollers, radiant tubes, sink roll, stabilizing roll, support arm and sleeve and other heat resistant alloy used for continuous galvanizing line(continuous annealing line), all kinds of heat treatment fixtures used for heating processing equipment, like tray, basket, fan and so on. Widely used for famous brand heat treatment equipment, such as IPSEN, AICHELIN, FONTON, etc.

We committed to the strict quality control and strictly implement ISO9000 series quality management system, Ensure the castings in each process of each station "zero defect" production, Quality has won the acceptance of customers at home and abroad.

Welcome to view our website: hexinmachineryqd.en.made-in-china.com

Qingdao Hexin Machinery Co., Ltd. produces furnace bottom rolls,which it adopt the centrifugal casting, precisely casting technology on journal bell mouth, shaft head with forging process. It can be transported with using professional wood packaging to the packing, its excellent quality has won high praise at home and abroad.

The grate system is the core part of the grate type waste incinerator.

It plays a vital role in the overall process route, incineration effect, project cost, economic benefit, etc.

The waste incineration grate is mainly composed of reciprocating moving parts.

The garbage is pushed onto the grate through the feeding device, heated at high temperature in the furnace, so that part of the garbage can be dried, and the garbage is pushed forward by the movement of the grate.

At the same time, the garbage layer is loosened, and the fuel (garbage) is gradually passed through the various stages of drying, ignition, burning, and burnout to make it completely burnt.

| Item | Incinerator grate blocks side walls |

| Process | Centrifugal/spun casting method for roll body, precision casting of assembly shaft head. |

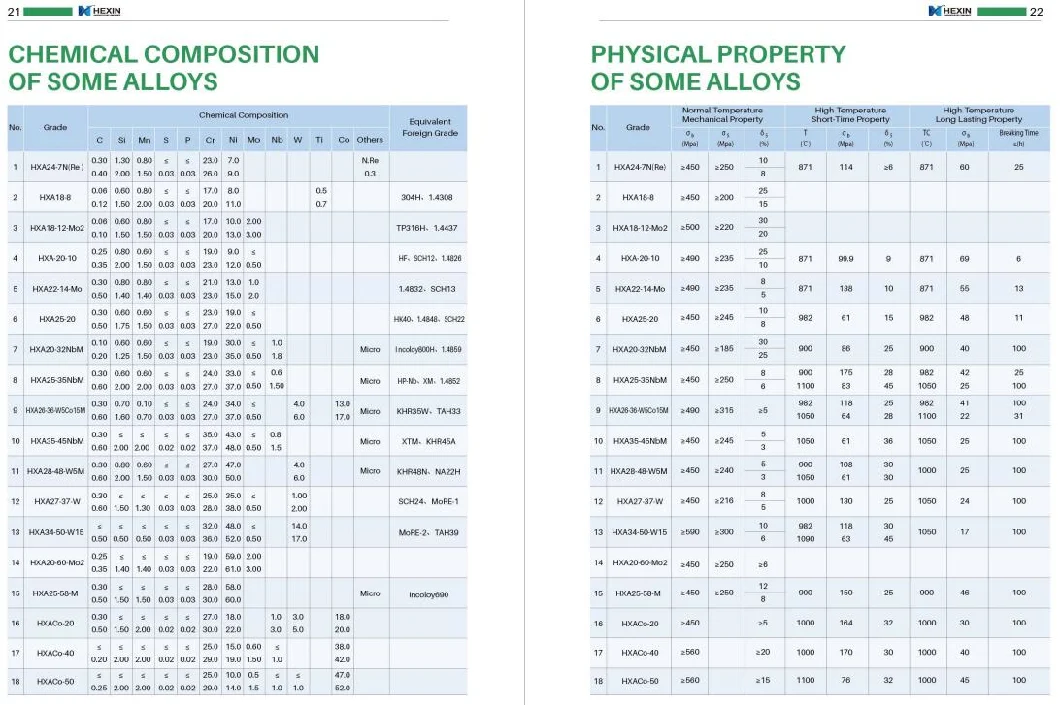

| Material | 316L,316,HK,HT,HU,HP,HH,ZG40Cr25Ni20Si2,ZG14Ni32Cr20Nb,ZG45Ni48Cr28W5Si2. |

| Application | The heat treatment furnace roll are usually used for normalizing furnace and hardening furnace, under the hydrogen nitrogen protective environment, Furnace temperature is about 900 ºC. CGL (Continuous hot dip galvanizing line),Plating aluminizing line, Plating silicon line. |

| Specifications | Outer diameter: 55mm-2000mm Length: as per your request |

| Test | Chemical analysis by spectrometer for each heat,eddy current test,pressure test ,thickness test , PT 100%(liquid penetrant test),VI(visual inspect)100%,dimensional check. |

| Products | Sink rolls Stabilizer rolls Furnace rolls for plate heating furnace Rolls for CAL Water cooled rolls Coated rolls |

About us

Qingdao Hexin Machinery Co., Ltd. is professional for manufacturing, sale and research of high temperature alloy centrifugal cast tube, Heat resistant steel precision castings and sand mold casting.

The main products are: Ethylene cracking furnace furnace tube, reformer furnace tube, all kinds of casting alloy elbow, casting tube sheet, hook, hanger, bracket and other heat resistant casting products. Furnace rollers, radiant tubes, sink roll, stabilizing roll, support arm and sleeve and other heat resistant alloy used for continuous galvanizing line(continuous annealing line), all kinds of heat treatment fixtures used for heating processing equipment, like tray, basket, fan and so on. Widely used for famous brand heat treatment equipment, such as IPSEN, AICHELIN, FONTON, etc.

We committed to the strict quality control and strictly implement ISO9000 series quality management system, Ensure the castings in each process of each station "zero defect" production, Quality has won the acceptance of customers at home and abroad.

Welcome to view our website: hexinmachineryqd.en.made-in-china.com