Basic Info.

Packaging & Delivery

Product Description

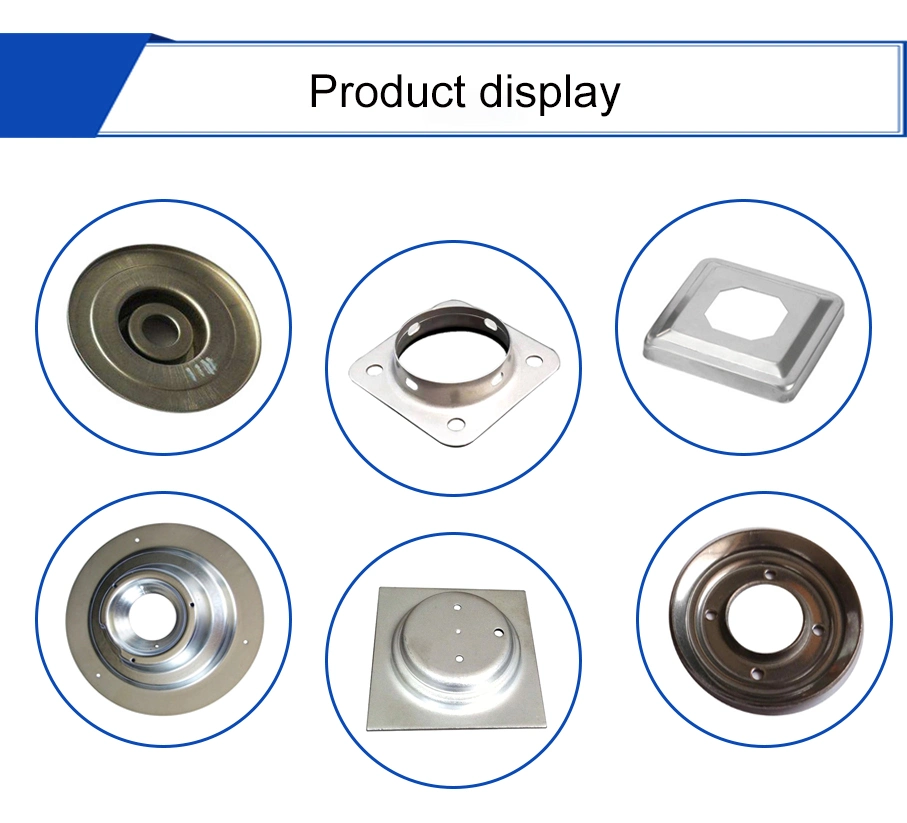

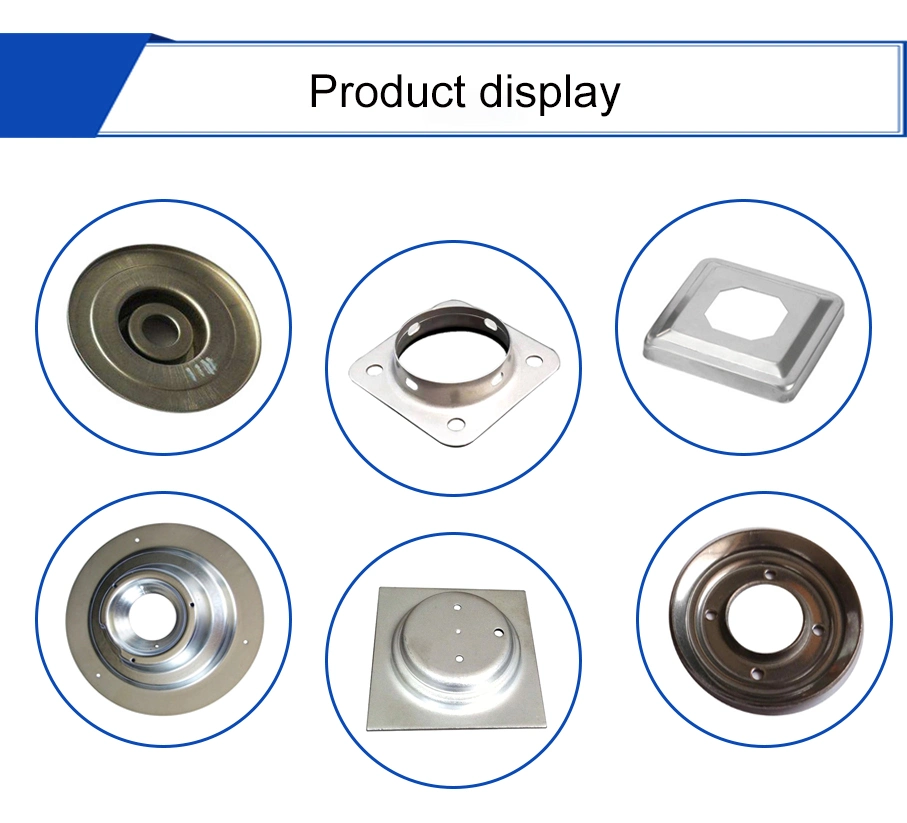

OEM Carbon Steel/Stainless Steel Deep Drawing Hardware Accessories

Our company philosophy:

Attention to Detail. Every quote we send out and every product we made is reviewed by a project specialist and

a knowledgeable manager, not simply run through an estimating or design computer. This personal attention, in conjunction with our profession,is what sets us apart from the rest of the field.

Competitive pricing. Our plant maybe not huge. Our office possibly is not gorgeous. But we have experienced engineers,well trained technicians and hearts full of responsibility. We run a highly efficient company.

We have been always looking for ways to produce a better product at a lower price.

Our experience. With around 20 years of experience in the metal processing industry, our knowledgeable team

has stood the test of time. We have mastered the art of tooling and fabricating quality product. Customized metal punching auto parts /components,Customized metal stamping auto parts, auto parts. stamping auto parts.

| Materials | Carbon steel(cold rolled steel sheet, galvanized steel sheet or tube), stainless steel, copper, brass, aluminum,etc. |

| Surface treatment | All kinds of surface treatment is available, polishing, zinc plating, nickel plating, chrome plating, powder coating, phosphate coating. |

| Measurements | According to customer's design,drawing or sample. |

| Mould/tooling/die | 1. We make the toolings by ourselves according to customer's drawing or sample. 2. We send samples to customer to confirm first 3. Single stamping die can save the cost if the quantities are not large.But the produce time is a little slow than progressive stamping die 4. Progressive die can save produce time for the large quantities products ,but the die's cost is expensive than single stamping die. |

| Confirm sample | If the first sample is not satisfied customer, we will modify the mould until customer satisfied. |

| Usage | Auto machinery parts, Funiture hardware, electronic hardware, construction machinery parts, metal processing machinery etc. |

| Sale market | Europe, Middle east, America, Africa ,South America etc. |

| Our Service | We will answer your email or inquiry within 12 hours |

Material

Material

* Steel

* Stainless steel

* Carbon steel

* Aluminum

* Spring steel

* Brass

Material thinkness-

* From 0.1 mm to 8mm

Why choose us?

1. High skilled and well-trained working team under good management environment.

2. Quick response and support for any inquiries.

3. Over 10 years professional manufacture experience to ensure high quality of your products.

4. Large and strong production capacity to meet your demand.

5. High Quality standard and hygienic environment.

6. We have very strict quality control process:

In coming Quality control (IQC) - All incoming raw material are checked before used.

In process quality control (IPQC) - Perform inspections during the manufacturing process.

Final quality control (FQC) - All finished goods are inspected according to our quality standard for

each products.

Outgoing Quality Control (OQC) - Our QC team will 100% full inspection before it goes out for

shipment.

Proper Quarantine procedure - For those products got rejected to pass the quality control, they will

specially marked and dispose.

7. Good after sales services

8. Passed ISO 9001 and provide SGS/ RoHS certification if needed.

Precision Manchinery

* Punch press 6.3 to 160 T

* Laser cutting machine

* Hydraulic bending machine

* Hydraulic shearer

* Welding machine

* Milling machine

* Polishing machine

* Assembly line

Product Range

* Stamping parts

* Laser cutting parts

* Automobile parts

* High precision sheet metal parts

* Precision progressive die

* Kitchen microchip

* Food machinery

* Welding parts

Surface finishes

* Zinc/ nickel/ chrome plating

* Powder coating

* Hot galvanized

* Painting

* Dichromate plating

Other specifications

* Advanced CMM measuring and testing equipment

* Advanced CAD, CAM and CAE technology, AutoCAD, Pro-E, Solid work 2001, CAXA, UG

* In-house tooling design and manufacturing

* Customized designs and specifications are accepted

* Meet RoHS compliance

You can look through our website to find your interest or email your any questions through

below approach! We will reply to you within 12 hours.

Material

Material