Basic Info.

Model NO.

ST-01

Applicable Industries

Construction Works, Energy & Mining

Weight

1000kgs

Video Outgoing-Inspection

Provided

Type

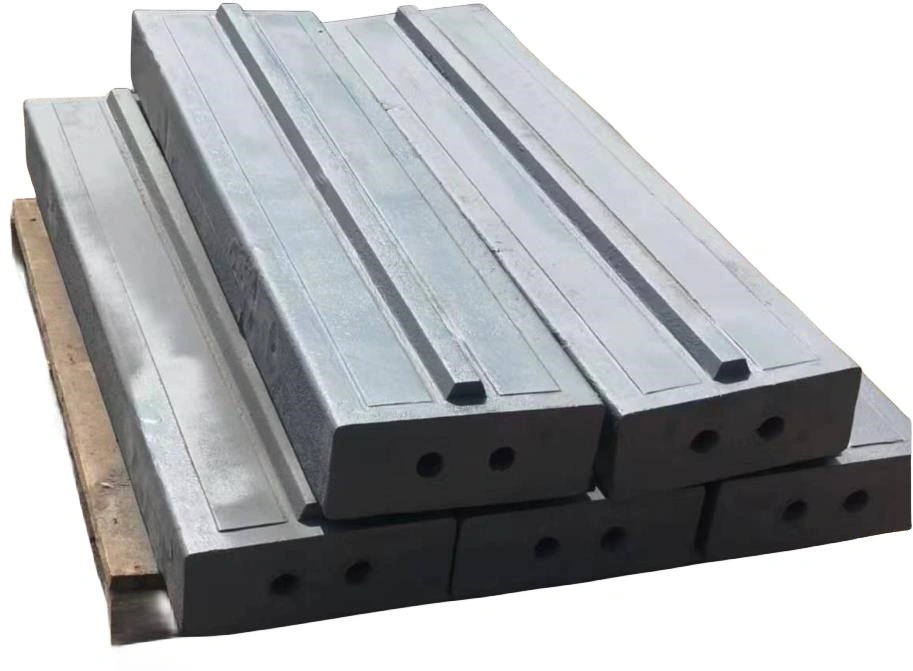

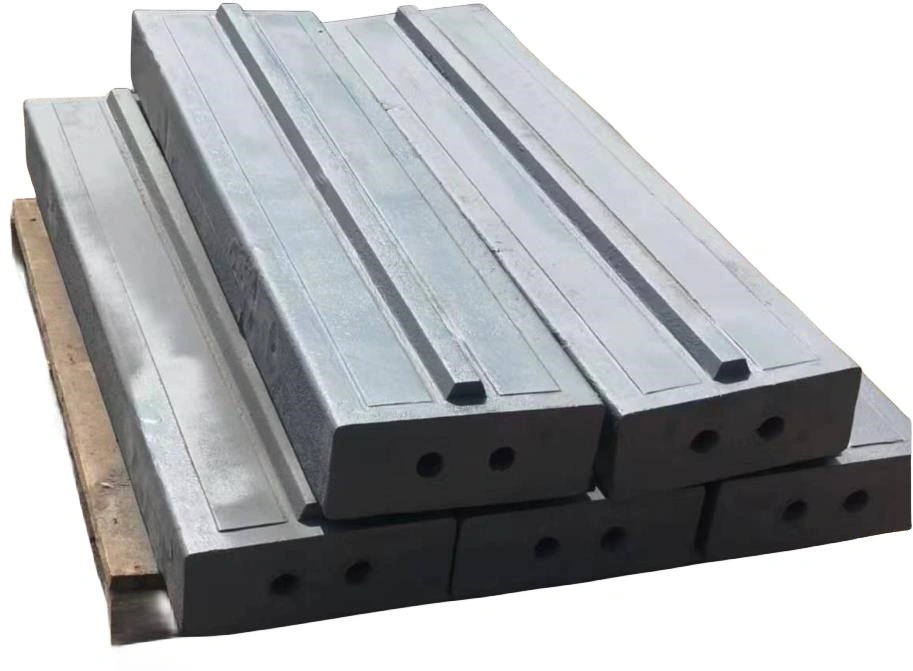

Jaw Plate

Machine Type

Crusher

Advantage

Wear Resistant

Quality

High Level

MOQ

1 Set

Transport Package

Wooden Case

Origin

China

Production Capacity

50000PCS

Product Description

Best price coal mill wear parts swing jaw plate wear parts impact crusher wear parts

High manganese and high chromium (or Martensitic steel) metal matrix insert ceramic insert mining wear parts composite casting products for mining equipment can double your wear resistance and impact resistance of castings. ceramic composite inserts casting products have jaw plates, cone liners, blow bars, hammers, grinding mill parts, and so on. We can make castings based on your drawings.

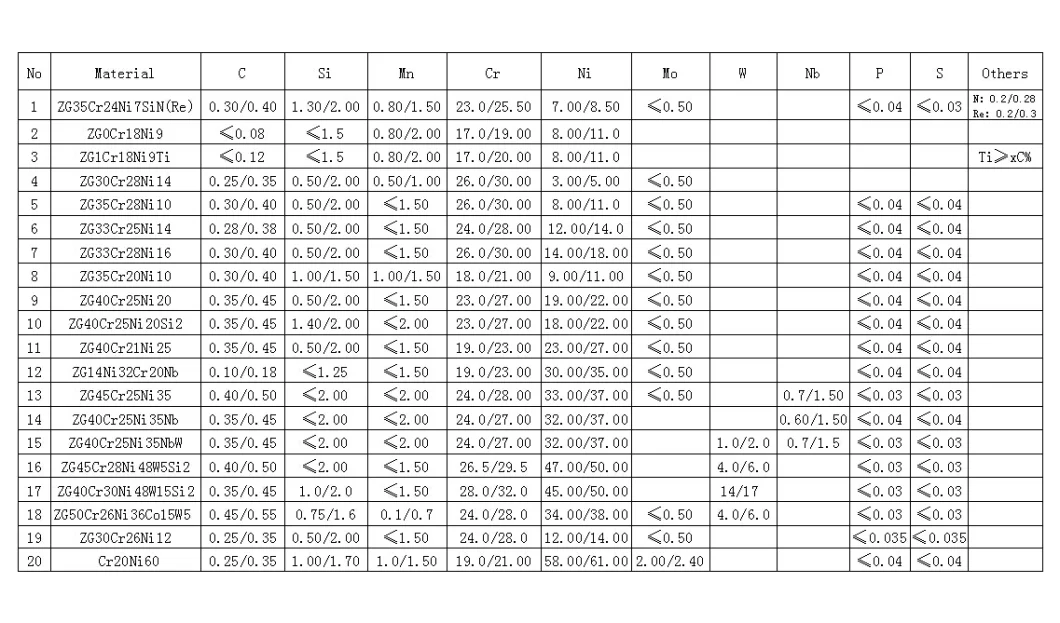

Quality Assurance:

1. Purchasing with quality, control the quality activity more on supply Chain and raw material

2. Establish the total quality roles and be responsible for every production link

3. Conduct the total quality management

4. Strictly carry out the quality control procedure

5. Testing System

Incoming raw material testing

Surface hardness testing

Core hardness testing

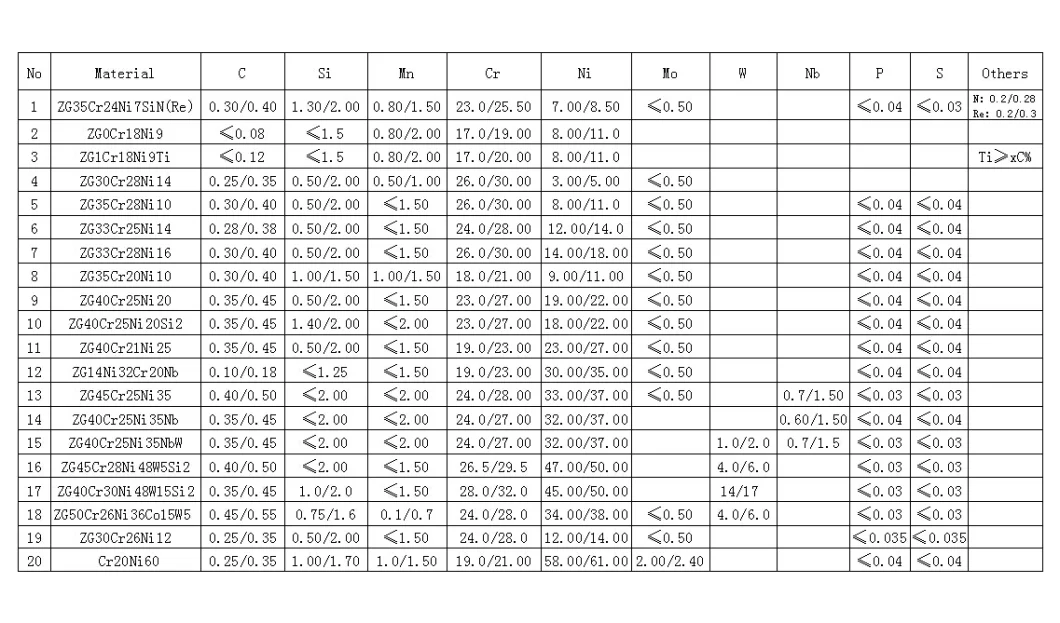

Chemical composition testing

Impact testing

Other testing required by customer

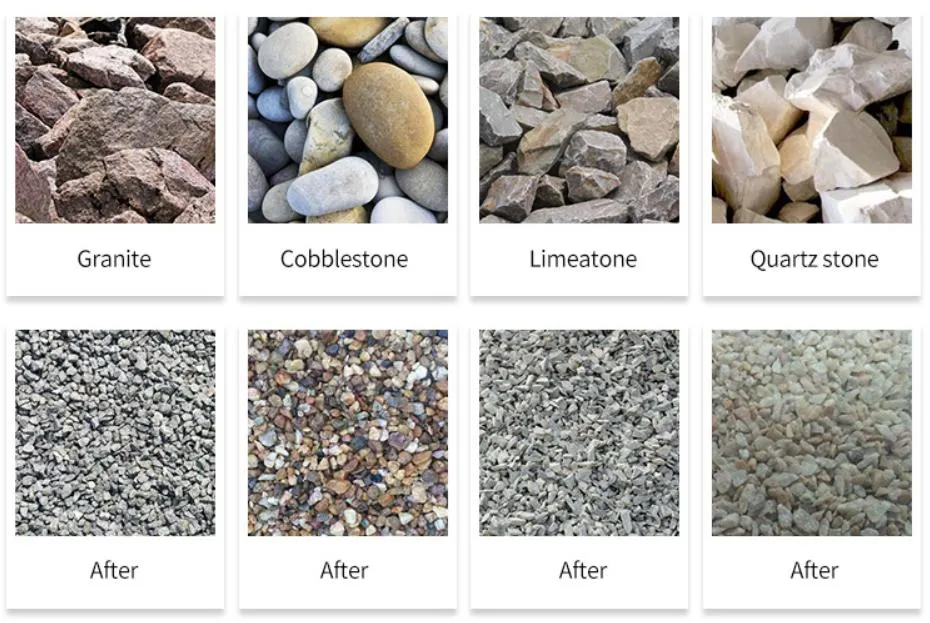

Application:

Our factory:

Our factory:

Category: Jaw crusher accessories

Main materials: high manganese steel, manganese-chromium alloy (Mn13, Mn13Cr2, Mn18, Mn18Cr2), cemented carbide

Main processes: water glass sand casting and lost foam casting process

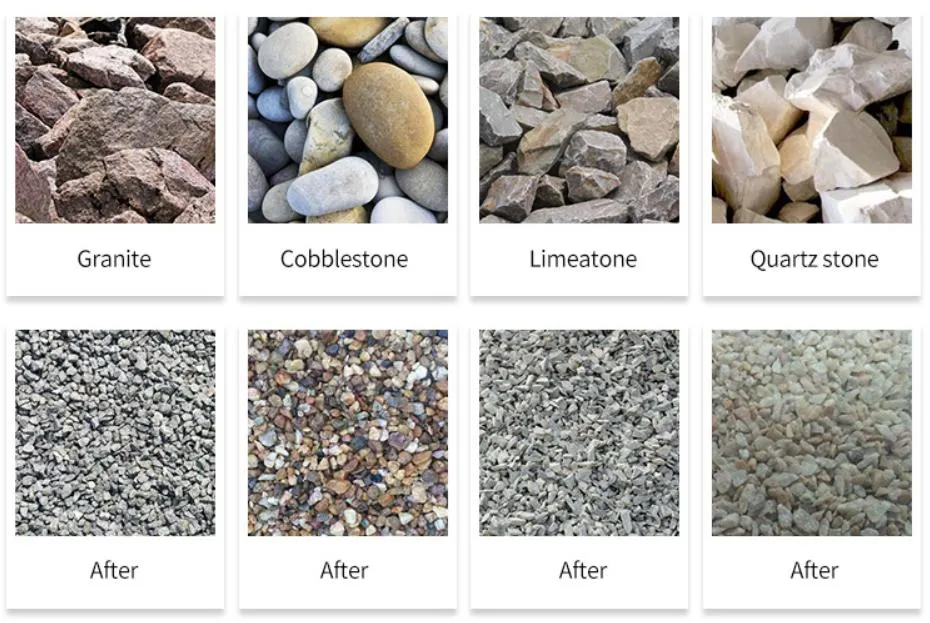

Applicable materials: river pebbles, granite, basalt, iron ore, limestone, quartz stone, diabase, iron ore, gold ore, copper ore, etc.

Q1: Are you a crusher wear parts manufacturer?

A: Yes, we have been producing the stone crusher and crusher wear parts for more than 15 years.

Q2: Which country have your products been exported?

A: We have been exporting business for 10 years and we have lots of customers and agents in the world, such as the United States, Russia, Mexico, Chile, Peru, Australia, Japan, South Korea, Thailand, South Africa etc.

Q3: If I need the complete mineral processing line, can you help us build it?

A: Yes, we can help you combine a complete mineral processing line and offer you related professional advice as per your

requirements. We had already built many mining projects in China and overseas.

Q4.What's the delivery time?

A: Generally it is 7-10 days if the goods are in stock. For customize, it will take 30 to 60 days after receiving your advance

payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Do you accept OEM business?

A: Yes, we are an OEM supplier.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

High manganese and high chromium (or Martensitic steel) metal matrix insert ceramic insert mining wear parts composite casting products for mining equipment can double your wear resistance and impact resistance of castings. ceramic composite inserts casting products have jaw plates, cone liners, blow bars, hammers, grinding mill parts, and so on. We can make castings based on your drawings.

| Size | 1kg-2400kg |

| Type | Base Tray, heat treatment fixtures, baskets, grate plate, parts of mining machinery |

| | Shanbao | PF series | PF1007,PF1010,PF1210,PF1214,PF1315,PF1320,PF1420,PF1620 |

| | CI series | CI711,CI712,CI721,CI722,CI731,CI732 | |

| CV series | CV215,CV216,CV217,CV218,CV228,CV229 | ||

| Trrio | APP series | APP4354,APP5148,APP5160,APP5560,APP6384,APP8084, | |

| APS series | APS3030,APS5148,APS5160,APS4034,APS4054,APS6084 | ||

| TV series | TV65,TV85,TV95,TVS115M | ||

| Telsmith | Secondary HIS series | HS2421,HS2430,HS3036,HS3048,HS4230,HS5252,HS5263,PA6060 | |

| KPI-JCI Astec | Andreas HIS series | 4233,4240,4250,5260 | |

| 5054 Hybrid HIS series | 5054 Hybrid | ||

| VSI series | 1500EV,2500EVT,3500EVT,4500EVT | ||

| Terex | Finlay | I-140,I-140RS,I-120,I-120RS,IC-110,IC-110RS,I-100,IC-100RS | |

| POWERSCREEN | 230,230SR,320,320SR,550,550SR,XV350 | ||

| MPS Cedarapids | TI4143,IP1516,IP1316,IP1313 | ||

| | EVO-LINE series | MR110Z,MR130Z | |

| QUARRY-LINE series | MR122Z,MR150Z,MR170Z |

Quality Assurance:

1. Purchasing with quality, control the quality activity more on supply Chain and raw material

2. Establish the total quality roles and be responsible for every production link

3. Conduct the total quality management

4. Strictly carry out the quality control procedure

5. Testing System

Incoming raw material testing

Surface hardness testing

Core hardness testing

Chemical composition testing

Impact testing

Other testing required by customer

Application:

Our factory:

Our factory:

Category: Jaw crusher accessories

Main materials: high manganese steel, manganese-chromium alloy (Mn13, Mn13Cr2, Mn18, Mn18Cr2), cemented carbide

Main processes: water glass sand casting and lost foam casting process

Applicable materials: river pebbles, granite, basalt, iron ore, limestone, quartz stone, diabase, iron ore, gold ore, copper ore, etc.

Q1: Are you a crusher wear parts manufacturer?

A: Yes, we have been producing the stone crusher and crusher wear parts for more than 15 years.

Q2: Which country have your products been exported?

A: We have been exporting business for 10 years and we have lots of customers and agents in the world, such as the United States, Russia, Mexico, Chile, Peru, Australia, Japan, South Korea, Thailand, South Africa etc.

Q3: If I need the complete mineral processing line, can you help us build it?

A: Yes, we can help you combine a complete mineral processing line and offer you related professional advice as per your

requirements. We had already built many mining projects in China and overseas.

Q4.What's the delivery time?

A: Generally it is 7-10 days if the goods are in stock. For customize, it will take 30 to 60 days after receiving your advance

payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Do you accept OEM business?

A: Yes, we are an OEM supplier.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.