Basic Info.

Model NO.

PC600*400, PC400*300

Finished Surface

Gear Process

Certification

CE, ISO

Condition

New

Color

Yellow

Model Number

PC800X600

Capacity(T/H)

15-30

Object

Iron Ore

Tongs′ Features

Adjustable Tongs

Cutter Material

Ceramics

Principle

Cylinder Culling

Name

Hammer Crusher

Transport Package

Standard Container

Specification

ISO9001-2008

Trademark

HengXing

Origin

Zhengzhou, China

HS Code

84742090

Production Capacity

15-30t/H

Product Description

Hot Sale Mining Ore Hammer Crusher And Pulverizer

Hammer crusher

A hammer crusher(hammermill) crushes material that is friable, by impacting it against a rotating hammer (typically traveling between 750 RPM and 1800 RPM). Then the material is forced against a rugged solid plate called a "breaker plate" which further degrades the particle size. Finally, the material is forced over a discharge grate by the hammers, where crushed finer particles drop through the discharge grate and larger particles travel around for another crushing cycle, until they fall through the discharge grid. During the entire time the material is traveling around in the hammermill it is constantly being impacted by the hammers, and the side of the mill casing, causing breakage of the particles. This sequence repeats itself between 750 - 1800 times each minute, until the particle is ground fine enough to fall through the discharge grid.

Hammer crusher and pulverizer Features:

1. Compact structure, easy maintenance

2. High wear-resistant hammerhead

3. Small investment, big returns

Hammer crusher

A hammer crusher(hammermill) crushes material that is friable, by impacting it against a rotating hammer (typically traveling between 750 RPM and 1800 RPM). Then the material is forced against a rugged solid plate called a "breaker plate" which further degrades the particle size. Finally, the material is forced over a discharge grate by the hammers, where crushed finer particles drop through the discharge grate and larger particles travel around for another crushing cycle, until they fall through the discharge grid. During the entire time the material is traveling around in the hammermill it is constantly being impacted by the hammers, and the side of the mill casing, causing breakage of the particles. This sequence repeats itself between 750 - 1800 times each minute, until the particle is ground fine enough to fall through the discharge grid.

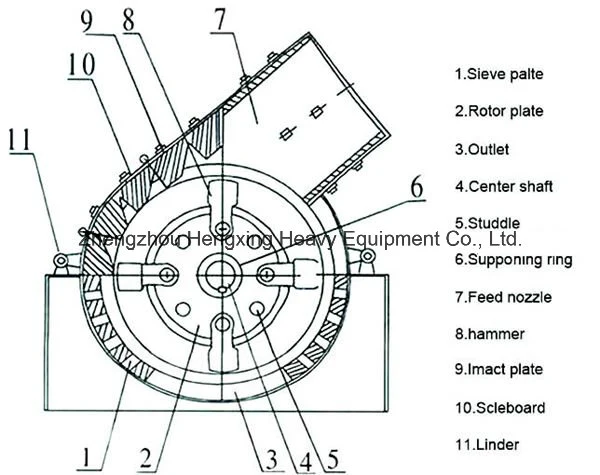

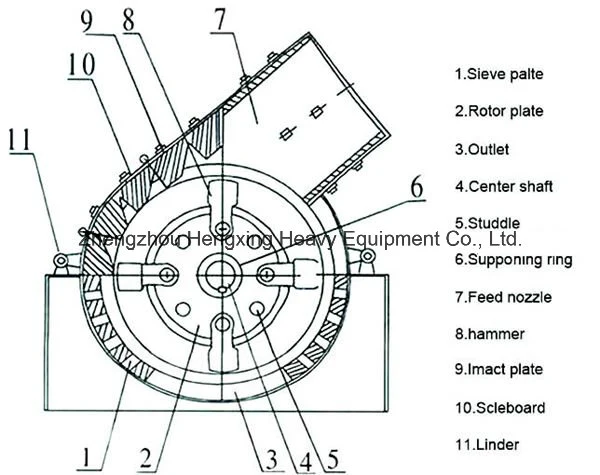

Hammer crusher and pulverizer Working Principle

The main working part of Hammer Crusher is the rotor with hammers. The rotor consists of main shaft, disk, hinge pin and hammers. A sieve plate is below the rotor. The motor drives the rotor to rotate at a high speed. When the materials get into the crushing cavity, they are crushed by the rotating hammers, the crushed products which meet the required size can be discharged from the sieve plate and become the final products, the products with larger size are brought back to the crushed area for being re-crushed until they reach the required size.

Hammer Crusher Main Technical Specifications

Hammer Crusher Main Technical Specifications

| Model | Rotor speed (r/min) | Input opening size(mm) | Max. feed size (mm) | Discharged Size (mm) | Capacity (t/h) | Power(kw) | weight (t) | Overall Dimension (L×W×H) (mm) |

| Φ400×400 | 1500 | 145×450 | 100 | 0-30 | 5-8 | 7.5 | 0.9 | 844×942×878 |

| Φ600×400 | 1000 | 295×450 | 100 | 0-35 | 10-12 | 18.5 | 1.03 | 1054×972×111 |

| Φ600×600 | 1000 | 295×570 | 100 | 0-35 | 12-18 | 45 | 2.14 | 1315×840×150 |

| Φ800×600 | 1000 | 350×570 | 120 | 0-45 | 20-25 | 55 | 2.45 | 1515×2586×10 |

| Φ800×800 | 1000 | 350×850 | 120 | 0-45 | 35-45 | 55 | 3.05 | 1515×2831×10 |

| Φ1000×800 | 1000 | 580×850 | 200 | 0-45 | 25-40 | 110 | 6.5 | 3206×2210×15 |

| Φ1000×100 | 1000 | 580×1060 | 200 | 0-45 | 40-80 | 132 | 7.6 | 3514×2230×15 |

| Φ1250×800 | 750 | 650×850 | 200 | 0-45 | 20-50 | 132 | 11.7 | 2630×1780×20 |

| Φ1250×125 | 750 | 650×1330 | 200 | 0-45 | 90-110 | 185 | 13.2 | 2630×2180×20 |

| Φ1400×140 | 750 | 1050×154 | 250 | 0-45 | 120-170 | 280 | 17.2 | 2790×2800×23 |

| Φ1600×160 | 600 | 1500×178 | 350 | 0-60 | 220-280 | 450 | 22.8 | 3350×3120×26 |

Hammer crusher and pulverizer Features:

1. Compact structure, easy maintenance

2. High wear-resistant hammerhead

3. Small investment, big returns

Contact:

Ms Sara Pang

Mobile phone 0086137 8347 1727